Compared with other types of shears, gantry shears have higher cutting efficiency, faster speed, and a wider range of cutting materials, especially suitable for cutting many and miscellaneous scrap metal materials.

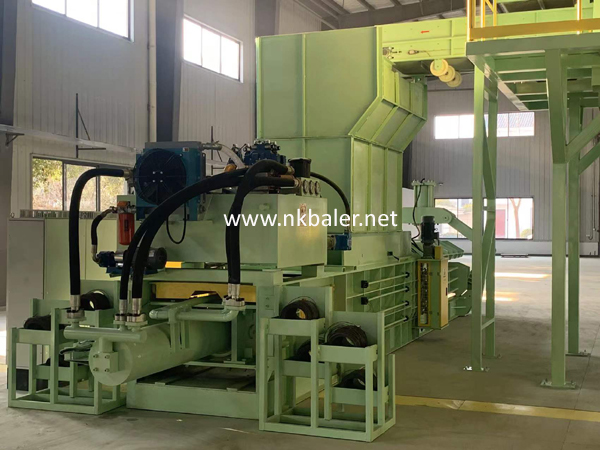

The automatic horizontal hydraulic horizontal baler adopts a horizontal structure. The rubber is transported by the conveyor to the silo of the automatic hydraulic baler. The oil cylinder is fixed on the frame with a flange. The vane pump is used as the power source. The horizontal baler, The hydraulic oil flows directionally under the control of the reversing valve, enters the rodless cavity or rod cavity of the hydraulic cylinder through the pipe, and pushes the piston to drive the pressure row to move back and forth, so as to achieve the purpose of cyclic compression. Repeat several times until the requirement is reached Up to the length, (the length is adjustable) automatically thread and tie the wire, and the compressed and packed materials will be delivered out of the box in order. Hydraulic valves include electro-hydraulic reversing valve and overflow valve, which have the function of preventing system overload. Large horizontal baler, reversing valve is sensitive and reliable. The structure is compact and reasonable, semi-automatic horizontal hydraulic baler manufacturer, beautiful and generous, stable operation, to achieve continuous production program control.

Hydraulic balers are widely used in the green and dry storage of forage grass in animal husbandry, and the packaging of garlic skins. It can save storage space and extend the feeding time of green straw. After packaging and sealing, it will naturally ferment to produce probiotics, beneficial bacteria, lactic acid bacteria, and protein, which will be naturally fermented. Cattle, sheep and other livestock will be easily absorbed after feeding, and the growth rate will increase. 2%, which greatly reduces the cost of feed transportation and storage, and reduces the labor intensity of workers. It has brought tangible economic benefits to the animal husbandry industry. It is one of the necessary products for the silage reclaiming of medium and large breeding plants.

As a well-known corncob Baler company, Nick has a huge consumer market and occupies a huge market share. It is in such a rapid development that we have seen that the corncob Baler has a broad development space in the market. The beauty of the corncob balers is worth having. The rapid improvement of the functions of the corncob balers has also made us realize that the corncob balers have great strength as packaging equipment in the new era. The reason why it is supported by the market is also because the corncob Baler shoulders the heavy responsibility and has a strong strength. The corncob balers will be more colorful tomorrow.

At present, many manufacturers of waste paper balers lack the awareness of protecting their own intellectual property rights. They have not applied for patents in all aspects for the new products and new technologies they have researched, and have carried out effective property rights protection. When this type of new products enters Soon after the market, it will be easily imitated by other manufacturers.

Email:info@nkbaler.com Nickbaler888@gmail.com

WhatsApp: 008615021631102