1. The use of straws in the form of mechanical return to the field, protective tillage, and return to the field can effectively improve the soil, improve soil fertility, reduce production costs, improve the quality of agricultural products, and help develop green agriculture.

2. Through silage, micro-storage and briquetting, the straw is converted into high-quality feed, which is conducive to promoting the development of animal husbandry.

3. The conversion of straw through the development of edible fungi is conducive to increasing farmers' income; the conversion of straw through biogas and vaporization is conducive to promoting the construction of new energy in rural areas.

4. Make full use of straw resources and inhibit straw burning, which can effectively control pollution, optimize the environment, and ensure the orderly progress of social and economic life. Can promote fresh air, smooth shipping and roads.

The development and utilization of straw is an important part of rural development of circular economy, an important aspect of improving comprehensive agricultural production capacity, and a major measure to improve the utilization rate of agricultural resources. The comprehensive utilization of straw is a cyclic process, and each link can produce direct economic benefits. Compared with the use of a certain method, the energy conversion rate and utilization rate of straw are greatly improved. The multi-level and multi-channel comprehensive utilization of straw in the recycling process not only reduces resource waste, improves environmental quality, but also creates wealth, absorbs rural surplus labor, realizes multi-level utilization of energy, and creates a material chain. The circular ecological agriculture model meets the modern agricultural development requirements of "sustainable, recyclable, recyclable, and reduced"

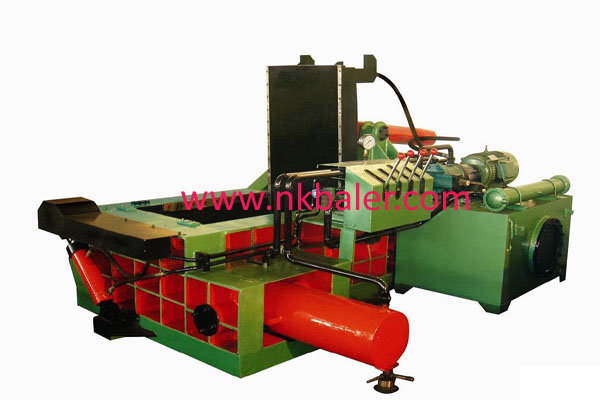

The emergence of metal chip briquetting machine and metal briquetting machine conforms to the production concept of enterprises, which not only saves energy, reduces costs, but also improves production efficiency and meets market development requirements.

1. The cotton baler has branch power supply and runs simultaneously with other machines, which will not only damage the performance of the machine, but also overdistribute and burn the plug and socket, which may cause a fire hazard. Special attention must be paid to prepare the special voltage and capacity only for this Baler Compactor.

2. The ground terminal of the packaging machine must be connected to the ground. There is a danger of electric shock if it is not connected to the ground wire or not fully connected.

3. The cross-sectional area of ??the wire using the extension cord is 0.75m㎡ and less than 10m. Using a flexible cord outside this range will not only damage the performance of the machine, but also overdistribute the plug and socket, which may cause a fire hazard.

4. When installing or packing super work, please be sure to use gloves, protective glasses, and masks. If it is not used, it may cause injury or harm to health.

5. The packing tape is used on the object to be packed. Do not use for other purposes. Packed objects refer to items that need to be packed.

6. Do not remove the panel, cover, door and other parts while using the machine. When the parts are removed, it will not only cause the machine to malfunction, but also easily lead to ginseng accidents.

7. Do not place the power cord in the forklift and other passages, or avoid directly pressing the power cord and other places. It is dangerous if the outer skin is damaged or disconnected.

8. Do not use wet hands to plug in and out the power plug, there is a danger of electric shock.

9. Packing items with water or moisture may cause electric shock.

10. When the baler is not in use, the plug on the socket must be unplugged. The insulation is degraded, causing electric shock or fire due to electric leakage.

11. When the heating plate is at a very high temperature, please do not put combustible materials near the back of the machine, as there is a risk of fire.

Nick Machinery is here to kindly remind you to take fire prevention measures to prevent fires. If you encounter other problems during use, you can contact our after-sales service 86-29-86031588

4. Reflecting the advantages of environmental protection, energy saving and energy saving, the metal materials after briquetting can be reused by enterprises and facilitate storage at the same time.

Email:info@nkbaler.com Nickbaler888@gmail.com

WhatsApp: 008615021631102