Nick reminds you that you must follow strict operating instructions during the use of the product, which can not only protect the safety of the operator, but also reduce the loss of equipment and extend the service life of the equipment.

Nick Machinery’s foam briquetting machine has simple structure, convenient operation and maintenance, high work efficiency, and low failure rate. Welcome to buy. 86-29-86031588

Nick Machinery has been engaged in the research of cola bottle Balers for more than ten years, and has a professional R&D team and after-sales team. If you encounter any problems during use, please contact us www.nkbaler.net

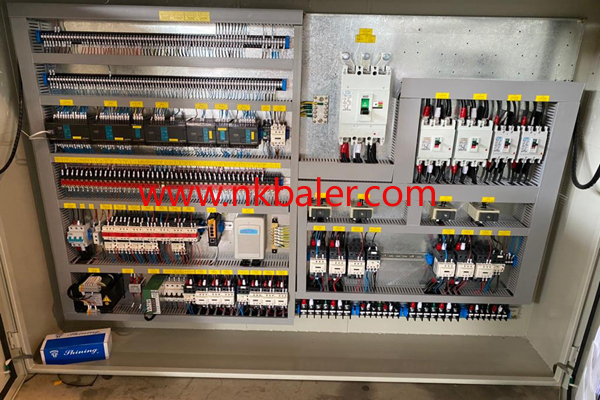

The above is a brief introduction of the baler control panel by Nick Machinery for you. For more details about the hydraulic baler, please visit www.nkbaler.net

Here, Nick Machinery reminds you that doing the daily maintenance and repair of the waste carton Baler can extend the service life of the Baler and improve the working efficiency of the Baler.

Email:info@nkbaler.com Nickbaler888@gmail.com

WhatsApp: 008615021631102