The historical development of the

wool baler is closely tied to the advancements in agriculture and industrial technology,particularly in the wool production industry.Wool,as a valuable commodity,has been an essential component of global trade for centuries,and the process of preparing it for market has evolved significantly over time.Manual Baling Era:Initially,

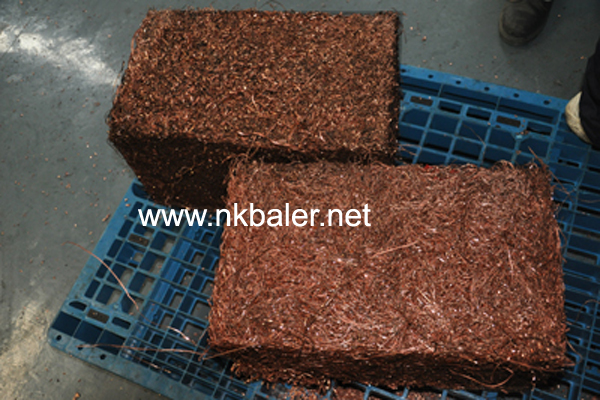

wool baling was done manually.Farmers and laborers would gather the wool by hand,often working on-site at farms or in warehouses after shearing.They would pack the wool into loose bundles or bags,which were then transported to markets or textile mills for processing.The Industrial Revolution:With the onset of the Industrial Revolution in the 18th and 19th centuries,the need for more efficient methods of baling increased.This period saw the introduction of machinery that could press the wool into more compact and uniform bales,making transportation and storage easier and more economical.Early baling presses were powered by hand or simple mechanical devices.Steam Power:As steam power became more prevalent in the 19th century,wool baling machines began to incorporate this new technology.Steam-powered baling presses could exert greater force,producing denser and more uniform bales.These machines significantly increased productivity and reduced the physical labor required for baling.

Hydraulic and Pneumatic Systems:By the early 20th century,hydraulic and pneumatic systems started to replace steam in many applications,including wool baling.These systems offered more control over the pressure applied to the wool,allowing for even greater consistency in bale size and density.Electricity and

Automation:With the widespread adoption of electricity,wool baling machines became electric-powered,offering yet another leap in efficiency and safety.The post-World War II era also saw the beginnings of automation in baling,with machines capable of handling larger volumes of wool with less human intervention.Computerization and Advanced Control Systems:In recent decades,computerization has played a significant role in the development of wool baling technology.Modern baling machines are often equipped with microprocessor controls that can regulate the compression,binding,and ejection processes.These systems may include sensors to detect bale size and density,adjusting the machine's operation for optimal results.Contemporary Innovations:Today's wool baling machines are highly specialized and can be customized to meet specific needs of different operations.They may include features such as automatic tying systems,integrated weighing scales,and even dust extraction systems to improve working conditions and product quality.Some machines are designed to handle various types of materials,not just wool,making them versatile for different industries.Sustainability and Renewable Energy:There is a growing trend toward sustainable practices in the wool industry,including the use of renewable energy sources to power baling equipment.Solar panels and other green technologies are being incorporated into some operations to reduce the environmental footprint of wool processing.Safety and Ergonomics:Modern baling machines prioritize operator safety and ergonomics.Safety interlocks,emergency stop mechanisms,and easy-to-use controls are standard features in newer models.The goal is to minimize the risk of injury while maximizing productivity and comfort for the operators.

Throughout its historical development,the

wool baler has transitioned from manual labor to a highly mechanized and automated process.As technology continues to advance,it's likely that these machines will become even more sophisticated,energy-efficient,and integrated with Internet of Things (IoT) capabilities for remote monitoring and maintenance.