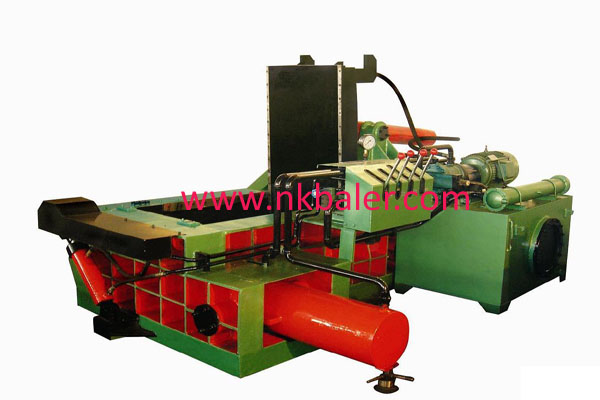

This machine is mainly composed of four parts: frame assembly, cylinder assembly, gear pump, and manual reversing valve.

1. Frame assembly: The frame is entirely made of steel welded structure, with strong resistance to pressure and tension, and pushes the bag.

2. Oil cylinder assembly: It is composed of the lower connecting plate of the oil cylinder body push rod piston sealing ring and so on.

3. Gear pump: adopt GB type standard gear pump (purchased), most of the parts are common.

4. The distributor is also called a manual reversing valve to control the direction of the hydraulic oil.

NKB240 bagging machine is a machine suitable for compressing and packing wood chips, chips, straw, paper chips, rice hulls, rice bran, cotton seeds, rags, peanut hulls, cotton fibers and other similar loose fibers. The machine size is 3960* 3030*1700mm, compression force can reach 60/80Ton, 45-50 packs per hour, high efficiency and high output. Let’s talk about his advantages

1. PLC control system, simple operation and precise control;

2. Packing and bagging, which can smoothly push the compacted block from the compression cavity into the packing bag;

3. One-key operation, compression, unpacking and bagging complete the whole process continuously at one time, which improves operation convenience and production efficiency;

4. The automatic feeding and conveying device uses the conveying line to increase the feeding speed and maximize the production.

With the development of science and technology, silage balers are becoming more and more common in agricultural life, which has brought us great convenience in production. So what are the advantages of silage balers? Let’s talk briefly.

1. Economical and practical, small, low energy consumption, high efficiency and quick results.

2. Simple operation, easy installation, stable performance, durability, and simple adaptation to the site.

3. The way to get rich is fast, the market demand is wide, the price of raw materials is low, sufficient, and renewable.

4. Low maintenance and simple maintenance at ordinary times.

5. One machine for multi-purpose silage, yellow storage, micro storage, hay bale, and packaging and bagging can be formed at one time, saving labor and effort.

The corn straw baler is mainly suitable for the packaging of loose materials, such as waste paper edges, cartons, straw, wheat straw, straw, beverage bottles, etc. The hydraulic baler is a mechanical structure, and some key components use domestic parts. Shaanxi Nick Machinery Manufacturing Co., Ltd. has a modern enterprise management mechanism, sophisticated processing equipment, professional testing methods, high-quality scientific research personnel, high-quality tracking services, and a high degree of professionalism to provide customers with satisfactory and economical technical services , Is a professional manufacturer specializing in the production of various hydraulic balers, and can provide various specifications of balers according to customer requirements. All products enjoy the specified three-guarantee service. The instruction manual and the three-guarantee card are included in the goods. The quality problem of the accessories is guaranteed within one year. , Replacement, return, and bear the packaging and transportation costs of accessories.

1. This machine adopts hydraulic transmission, highly integrated valve block, super large flow diameter, so that the system pressure loss is small, and the sealing performance is good.

2. The use of cartridge valve, electro-hydraulic proportional valve and unique oil circuit design make the hydraulic system perfect. Even if it works under long-term heavy load, the system will not appear to be inadequate.

3. The system is designed with a pre-discharge device, which completely eliminates the hydraulic shock.

4. Advanced fast device to ensure your hourly output.

Nick brand scrap aluminum briquetting machine has simple structure, convenient operation and maintenance, and is a good helper for your production. If necessary, please contact www.nkbaler.com

Email:info@nkbaler.com Nickbaler888@gmail.com

WhatsApp: 008615021631102