3. Common motor faults.

When the small horizontal waste paper box baler is not used, be sure to unplug the power plug from the power socket. The switching power supply was cut off to prevent electric shock or fire accident caused by power failure. When the heating plate is at a very high temperature, do not put flammable objects around the back of the device, there is a risk of fire accident. Please be sure to carry out actual operations in accordance with regulations.

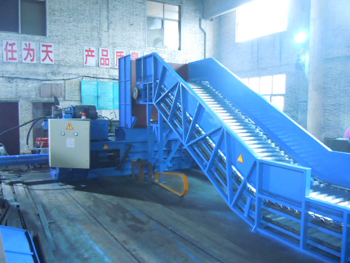

Shaanxi Nick machinery equipment can supply many kinds of baler machine

Waste paper baler machine ,plastic baling machine ,metal press ,sawdust bagging machine ,rice husk baler machine ,rag bagging machine ,tire baler machine ,used cloth baling machine ,and many kind of strapping machine ,compactor ,baling press machine as so on . for more information ,please visit : www.nickbaler.net or www.nkbaler.com even you can send us whatsAPP:00 86 15021631102 to free talk and inquiry as any time .

1. Advantages: Crush the straw into fine sand from the source. It can be used in many places, such as reservoirs, coastal areas, etc., providing drying equipment, which can be used for production in forests, rice fields, nurseries, houses, etc. Using sulfide as fuel, stacking equipment, low noise, clean and sanitary. It saves space and occupies less area, and is easy to repair and maintain. Under certain conditions, a restaurant and kitchen waste landfill can even be formed around the reservoir, which can be used for secondary treatment of the environment, reducing investment and pollution.Shaanxi Nick machinery equipment can supply many kinds of baler machine

Waste paper baler machine ,plastic baling machine ,metal press ,sawdust bagging machine ,rice husk baler machine ,rag bagging machine ,tire baler machine ,used cloth baling machine ,and many kind of strapping machine ,compactor ,baling press machine as so on . for more information ,please visit : www.nickbaler.net or www.nkbaler.com even you can send us whatsAPP:00 86 15021631102 to free talk and inquiry as any time .

6. The oil added to the oil tank must be rigorously filtered, and should always adhere to a sufficient amount of oil. If there is a shortage, the oil should be added immediately. The straw baler is filled with smooth oil every 1.5 hours, and 5 to 6 times less smooth oil is added to each smooth part of each shift (8 hours).

Shaanxi Nick machinery equipment can supply many kinds of baler machine

Waste paper baler machine ,plastic baling machine ,metal press ,sawdust bagging machine ,rice husk baler machine ,rag bagging machine ,tire baler machine ,used cloth baling machine ,and many kind of strapping machine ,compactor ,baling press machine as so on . for more information ,please visit : www.nickbaler.net or www.nkbaler.com even you can send us whatsAPP:00 86 15021631102 to free talk and inquiry as any time .

For mechanical and electrical equipment, automation, intelligence, and unitization make the design thoughtful, and its important parts must be considered. The service life of each product is determined by a core component, and that core component is often a valuable one. For example, the core component of the baler is the movement; the core component of the sealing machine is the motor; the core component of the heat shrink machine is the furnace; the production of the winding machine has been modularized, and the core component is in each module. The core component of the vacuum packaging machine is the vacuum pump. Most small vacuum packaging machines now use rotary vane vacuum pumps.

3. It has a wide range of applications. It can be used as a processing equipment for packaging waste plastic film, and can also be used as a processing equipment for packaging and compacting similar products.

for more information ,please visit us : www.nkbaler.com or whatsapp us :+86 15021631102

Email:info@nkbaler.com Nickbaler888@gmail.com

WhatsApp: 008615021631102